One of the problems with having a public blog like this and having co-workers follow it is the hard time they give me at work. “What have you done for me lately?” That’s okay, it’s another incentive to keep moving ahead.

By the way, I’m dabbling in the stock market with intended future Jag funds. I’ve never been an active market investor so I’m learning a lot. Jim Cramer is my new best friend. Brad, overhearing Gary teaching me a few things, suggested a three month fantasy stock challenge with some arbitrary constraints. We’ve got five guys in it, including Gary and Bob. Now I fully expect Gary and Bob to leave my picks in the dust. Or at least I wouldn’t be embarassed to be schooled by them. Brad decided to replicate the monkey-throwing-darts technique. So for his picks he blindly dropped a pen onto a Wall Street Journal spread on his desk.

Here’s the problem. After the first week his dart-throwing monkey picks are kicking my ass. So please e-mail me your illicit insider information. It’s a good cause and … good enough for Martha Stewart, good enough for me!

That Verizon FIOS install went smooth as a baby’s butt. The internet sure is snappier at 5/2 MPS speed. I didn’t want to make a polishing racket while the installer dude was here. Maybe I’d be able to hear him falling off the roof. So I didn’t finish the valve cover. I started rebuilding the SU HD8 carbs instead. Move valve cover polishing next time, I promise. I know you want it.

I’m getting smart. Well, smarter anyway. Here I am, wearing my personal protective gear for polishing.

Ready to rock and roll. That’s a dust mask, face shield, and ear plugs. The polishing motor is pretty loud. Technically those are isolating ear phones going to an Ipod so I can be mellow while I polish. Polishing debris still gets everywhere but this seems like a reasonable compromise.

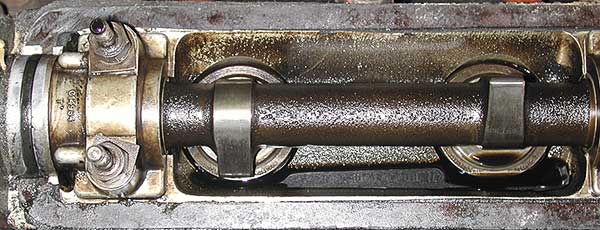

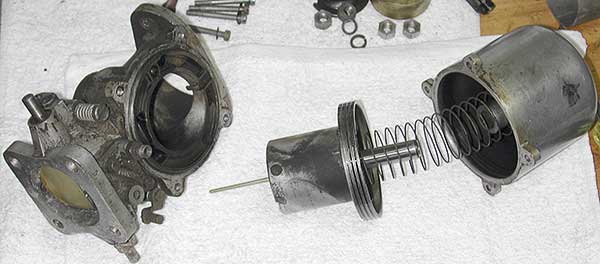

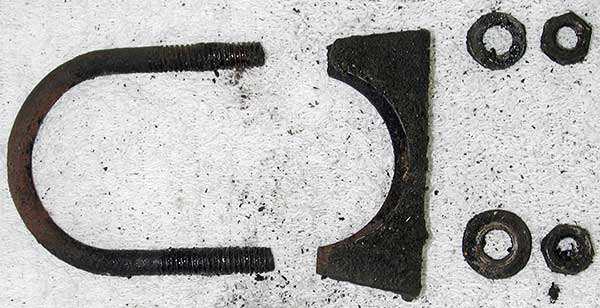

Here’s an exploded view of the challenge.

No, not quite as organized as the repair manual photos. This book (see below) was helpful in showing a good rebuild order and some tips on techniques and settings. It does not have exhaustive step-by-step but the important points seem to be covered. I don’t believe this book alone would be enough for me to rebuild the engine by myself. And the Moss DVD I mentioned below was also useful.

Speaking of books, I happened to purchase Jaguar World’s “Jaguar E Type Restoration” book from an English seller recently. That book is a collection of the magazine’s photo coverage of two E-Type restorations, a Series 1 4.2 and a Series III (V-12). While not exactly my car, the other Series 1 is close enough to be of interest. If you go to Amazon or other American book sources you’ll see absurd prices on this book, somewhere around $200 !! I think it is the Jag club in the UK that promotes reprints. Anyway I got it for 23 GBP, with shipping, from VW-DIY.com . Now that I have it I wouldn’t call it a must-have item but the more texts I can find the better.

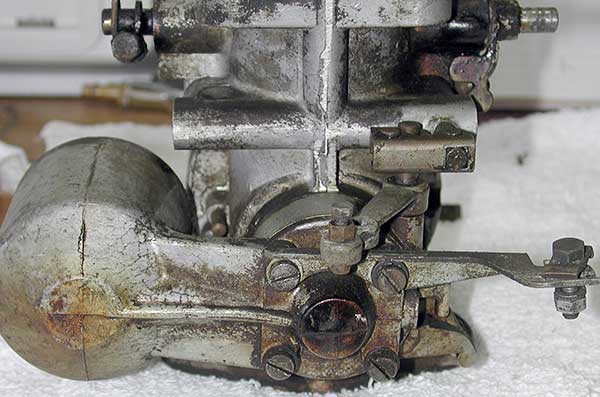

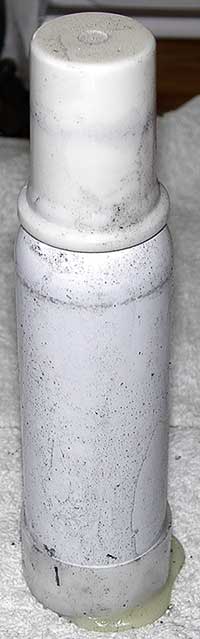

Here is the “Grose jet” replacement for the original carb float valve I mentioned before.

You can see the big lower ball that pushes up against another ball you can’t see. Its random rotation means it should continue working long after the needle on the right starts leaking. You wouldn’t think the Series 1 fuel pump pressure of 3.5 PSI or so would be a big deal but fuel leaks on a hot engine are bad news. Sort of like water leaks for a boat.

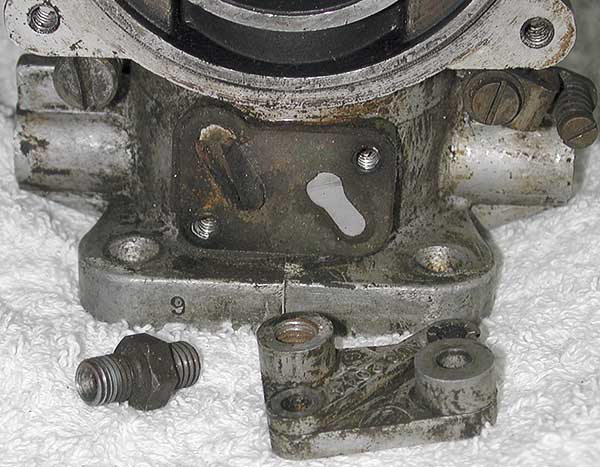

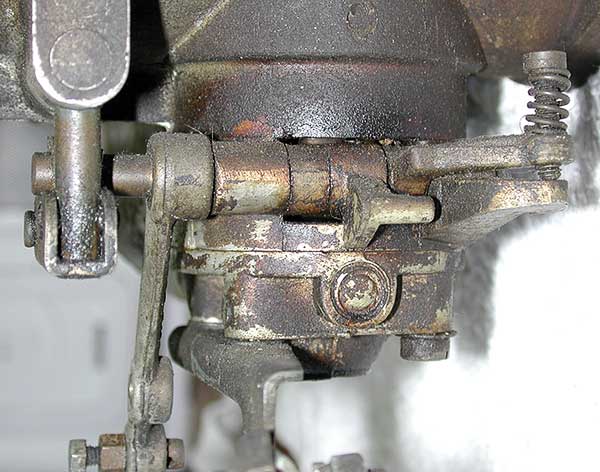

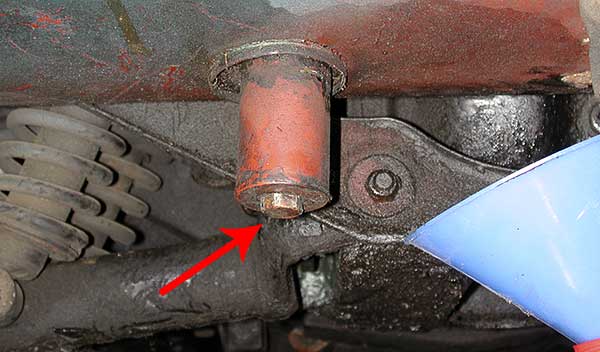

Here is one of the end caps for the throttle shaft. These retain a spring against the cork seal and its dished washer. They are difficult to remove from crusty carbs without some pry damage.

The Moss DVD taught me a neat trick. Slide it over a close-size socket.

Now flip it upside down against a flat hard surface and tap the socket with a hammer.

Not perfect but very serviceable.

The new cork seals in rebuild kits should be soaked in oil for a while before installation.

This reduces the chance of damaging them when you insert them and when you push the throttle shaft through.

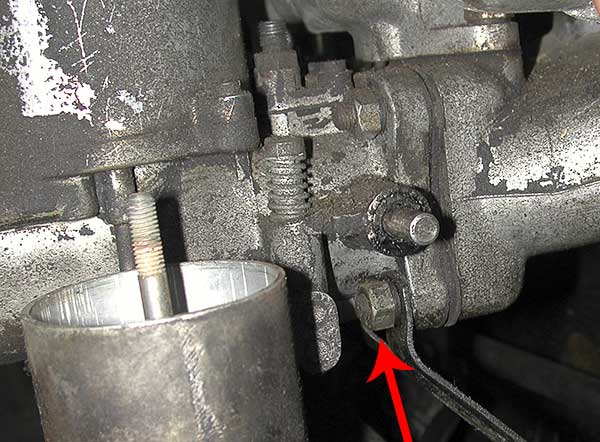

Here is the replacement kit for the “slow run screw” I showed you before that was a bit chopped up. Can you believe the screw was not separately available? There are a couple of parts, like those small springs and screws that must belong on other SU carb versions.

Here is one way to measure the float height. The forked arm is supposed to fully engage the shut-off pin (now Grose jets) 11.1 mm above the ridge of the float lid.

You bend the arm at the end of the straight section to adjust. This is the hard way of doing it. As shown in a prior post, I purchased a small SU carb tool kit. One of the items was an oval tube with just the right width.

Still sort of an awkward task. The usual reason carb float shut-off height is important is because it affects how lean or rich the carb runs by changing the fuel height that the main jet draws fuel from. If fuel is sitting too high it’ll run rich and vice versa. I assume that is also true of the SU’s?

Here is the stack of parts that screws the overflow tube onto the float bowl. I believe the identification tag is supposed to be above the banjo fitting, not below as shown here.

Strange thing. Not ONE of my manuals, including the official Jaguar parts manual, shows the carb ID tags. What’s up with that? It also means I’m not sure if the tag is just inserted under the top washer or if I need to sandwich it with an extra plain washer. One of mine came apart that way but the other two did not. Probably not a critical item. All that seal has to resist is a 1/4″ or so of fuel height before it flows down the open overflow tube.

Here is the first little jewel, the front carb, finished on the bench. Yeah, I know, the ID tag is still wrong. Don’t bother e-mailing me on that. I fixed it after the photo op.

Now I got into a rhythm by the third, rear, carb and (can you see this coming?) I assembled its float bowl backwards. I knew it was reversed but my brain was on cruise control. Not too much work to fix it but I was tired and dopey at that point. Okay wise guy, dopier than usual.

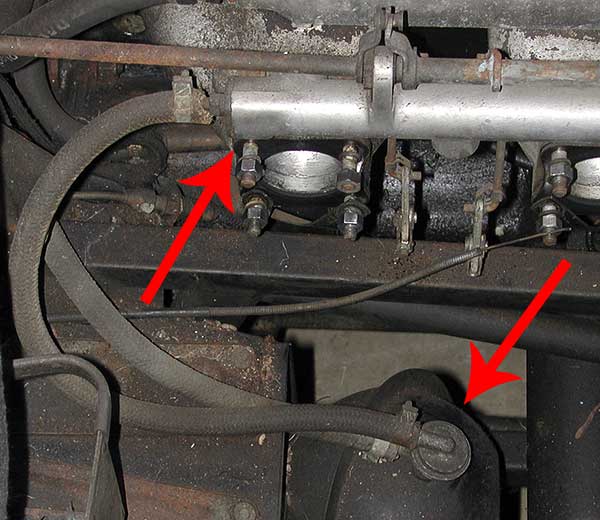

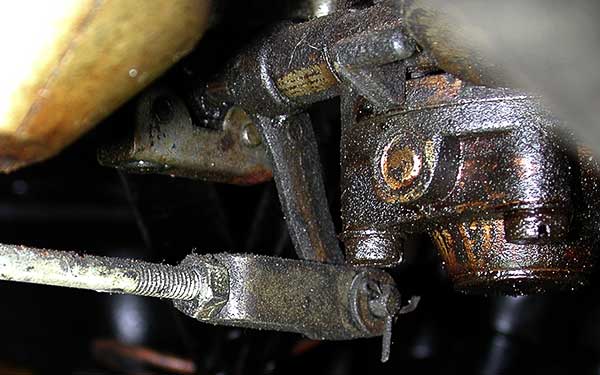

The throttle shaft return spring is connected between the shaft and an arm that is bolted under the carb. The paint on those arms was peel and rusty. A soak in Evapo-Rust worked on the rust. Some Krylon primer and gloss black brings us to this.

One of my new favorite phrases comes to mind, not perfect but serviceable. Maybe that’ll be on my future family crest?

I pushed on into the night because I was close enough to taste carb victory. The rear carb’s main jet was also the most stubborn to center. I must have moved the jet holder five times until I found a satisfactory fit. It still has a little more stiction than the other two carbs but I think that is slight piston corrosion. The piston still drops freely to the bottom. We’ll see if that’s a problem later.

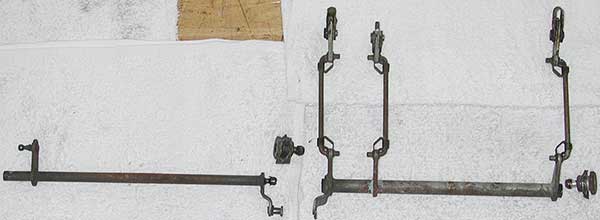

And here are the three carbs, mounted to their intakes and with outer gaskets taped on. I figure that’s as good a place as any to keep the gaskets, no?

I dub thee, The Three Amigos!